Free Copy Of Iso 2859 1

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Wed Jun 28. 3.10 Drawing a sampling plan from the tables in ISO 2859-1. This does not preclude the free use, in the course of implementing the standard, of. Iso 2859-3, iso 2859-4, iso 2859-5 and iso/tr 8550-1. The individual parts of this series of international standards extend this introductory explanation to more specific applications that are appropriate for the particular standard.

This article introduces the different options available to buyers when it comes to the representativity of inspection findings.Inspection level II (under “normal severity”) is appropriate for most inspections. But it is sometimes necessary to increase–or reduce–the number of samples to check.The need for sampling, rather than 100% checkingWhen controlling the quality of a batch of products, it is not practical to inspect 100% of them (unless the quantity is very small). Inspecting a large number of products takes a long time: it is expensive, and inspectors are less effective as they get tired.

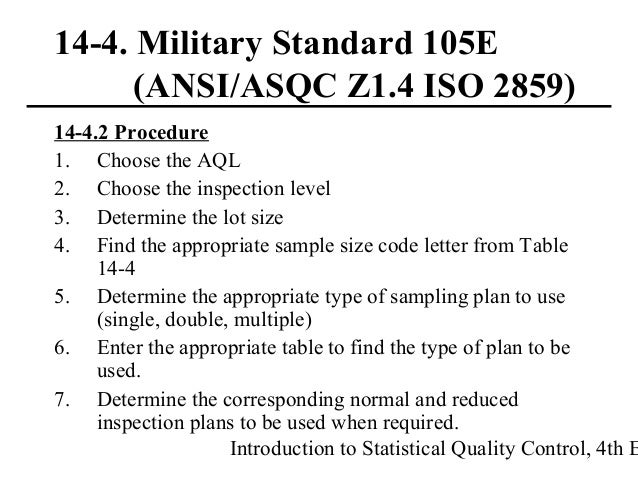

Actually, a 100% check does not yield that much more information than inspecting a statistically representative sample.The question becomes: how many products to check?Why different inspection levels?There is a fairly obvious principle in statistical quality control: the greater the order quantity, the higher the number of samples to check.But should the number of samples ONLY depend on the order quantity? What if this factory had many quality problems recently, and you suspect there are many defects? In this case, you might want more products to be checked.On the other hand, if an inspection requires tests that end up in product destruction, shouldn’t the sample size be drastically reduced? And if the quality issues are always present on all the products of a given batch (for reasons inherent to processes at work), why not check only a few samples?For these reasons, different levels are proposed by MIL-STD 105 E (the widely used standard for quality control in the form of acceptance sampling). By the way, that standard has formally been replaced by various commercial standards (ISO 2859-1, ANSI/ASQ Z1.4, and so forth).It is usually the buyer’s responsibility to choose the inspection level– more samples to check means more chances to reject bad products when they are bad, but it also means more days (and dollars) spent in an inspection.The 3 “general” inspection levelsLevel IHas this supplier passed most previous inspections? Do you feel confident in their products quality?

Iso 2859 1 Free

Instead of doing no quality control, buyers can check fewer samples by opting for a level-I inspection.However, settling on this level by default, in order to spend less time/money on inspections, is very risky. The likelihood of finding quality problems is lower than generally recommended.Level IIIt is the most widely used inspection level, to be used by default.Level IIIIf a supplier recently had quality problems, this level is appropriate. More samples are inspected, and a batch of products will (most probably) be rejected if it is below the quality criteria defined by the buyer.Some buyers opt for level-III inspections for high-value products. It can also be interesting for small quantities, where the inspection would take only one day whatever level is chosen.Watch this video and learn how to improve management of quality from Chinese & Asian suppliers. The 4 “special” inspection levelsThese special levels can be applied in cases where only very few samples can be checked. “Four additional special levels, S-1, S-2, S-3 and S-4 may be used where relatively small sample sizes are necessary and larger sampling risks can be tolerated” (ISO 2859-1 standard).Under S-3 level, the number of samples to check is lower than under S-4, and so on.In practice: for consumer goods, quality control is usually performed under the general levels.The special levels are used only for certain tests that either take lots of time or destroy the samples. Another situation where special levels are appropriate is a container-loading supervision–to have an idea of what is inside the cartons, without spending too much time at that checking.Two examples to get a clearer understandingLet’s say you have ordered 5,000 pcs of a product.

In the table below, you can see how many samples would be drawn under each of the 7 inspection levels. General inspection levelsSpecial inspection levelsIIIIIIS-1S-2S-3S-480pcs200pcs315pcs5pcs8pcs20pcs32pcsAs you can see, the numbers of samples to check vary from 5pcs to 315pcs. But a trained inspector might be able to do it in one day, whatever the inspection level you choose.Now let’s say you have ordered 40,000pcs of a product.

Again, you can see the differences in sample sizes. Hi Renaud, im new to this, and looking to start an import agent business in Australia. I’ve got my head around a lot in the last 5 months. The supplier information is incredibly detailed though.

Free Copy Of Iso 2859 1 Standard

However your website is an excellent source.To start with i’m unsure if I will be representing small or large orders, I hope both. In this case, after reading through your website I will be making it known to my customers that they have to get a quality inspection. Would it be best to advise the people I represent, get a Quality inspection at the end of production for a small order? And a quality inspection at the beginning, during and after large orders? After all it is their livelihoods, and it would be a small price to pay right? Also I can say that i’ll be importing rattan and wicker furniture, and other wood type products for the home. I’m unsure if that will include OEM products, do I need to know more about of OEM?

Iso 2859 2017 Pdf

I don’t know much specifics on this?.tom says. I will do my own research in finding and verifying my own sources, but can anyone tell me a supplier that can produce rattan and wicker furniture in thailand,ive had trouble locating some, even on alibaba. I get some but it’s more trading companies.Also If I’m an import agent, is it beyond the possiblity to buy from a trading company? It seems I may not get a good enough price.Renaud do you have a quality control company based in Thailand? Or can you point me in the direction to a good one?Thanks everyone, Tom.Renaud Anjoran says. Ben,Your numbers are right.Under reduced severity and S-3 level, C is 2 pcs, and under 1.5% it becomes 3 pcs.But I don’t think you should tweak the numbers like this.

You don’t HAVE to follow the arrows, as indicated in paragraph 10.3 of the standard:“When no sampling plan is available for a given combination of AQL and sample size code letter, the tables direct the user to a different letter. The sample size to be used is given by the new sample size code letter, not by the original letter.

If this procedure leads to different sample sizes for different classes of nonconformities or nonconforming items, the sample size code letter corresponding to the largest sample size derived may be used for all classes of nonconformities or nonconforming items, when designated or approved by the responsible authority. As an alternative to a single sampling plan with an acceptance number of 0, the plan with an acceptance number of 1 with its correspondingly larger sample size for a designated AQL (where available) may be used, when designated or approved by the responsible authority.”.Tom says.

Titled “Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection” has just been modified by a dated 6/15/2011.The 8 page amendment makes pen-and-ink changes to a number of pages. Changes include updates to references to other ISO standards and to accommodate the scoring roles of switching.The document itself is one of a series of 6 standards on Sampling procedures for inspection by attributes. Part 10 is now the general introduction, with Parts 1 to 5 each defining a particular type of inspection.